Recovery of noble metals from dusts

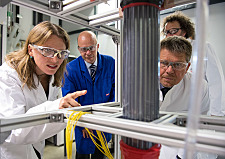

How can commercially strategic metals and metal compounds be physically separated from dusts in the circular economy? This question is being addressed by Bremen University and its partner Ventimola GmbH & Co. Dämmtechnik KG in an ongoing project. The aim is to demonstrate both technical and commercial feasibility via a case study.

The proposed physical processing offers the potential for the recovery of a number of other commercially strategic metals from waste material. The source of the raw material is the large quantities of dusts which so far have been discarded.

Unlike in conventional gold extraction, no use is to be made of chemical processes like cyanide leaching. In the case of cyanide leaching, the gold-bearing rock is crushed into a fine powder. Sodium cyanide is then used to dissolve the gold contained in the powder. It is then dissolved in the highly toxic slurry leach, precipitated using zinc dust, reduced to raw gold, and refined to produce marketable fine gold.

The project was financed with funding from the European Union and the State of Bremen, the Senator for Climate Change Mitigation, Environment, Mobility, Urban Development and Housing Construction, the Applied Environmental Research funding programme.

This project focus on innovation an is supported by our heroine Felicia